Thermal imaging cameras have transformed the way professionals assess and troubleshoot building structures in the field of building diagnostics. These advanced tools make it easier to identify moisture issues, which can be a major concern for property owners. By capturing infrared radiation, thermal imaging cameras provide valuable insights into energy efficiency, structural integrity, and potential water damage. Whether you're a building inspector, energy auditor, or facility manager, using a thermal imaging camera can significantly improve your diagnostic process. In this blog, we'll explore the various applications of thermal imaging in building diagnostics and highlight the benefits they offer.

What is Thermal Imaging?

Thermal imagers are devices that detect the infrared radiation emitted by objects and create a thermal image based on temperature differences. Unlike traditional digital cameras that rely on visible light, thermal imaging cameras use heat signatures to produce images. This technology has revolutionized many industries around the world, allowing us to see what our eyes cannot normally detect. Initially used for military and security purposes, thermal imaging has now expanded into numerous fields, including construction, energy auditing, and building maintenance. With modern advancements, these cameras are more accessible and widely used for a variety of practical applications.

Key Applications of Thermal Imaging Cameras in Building Diagnostics

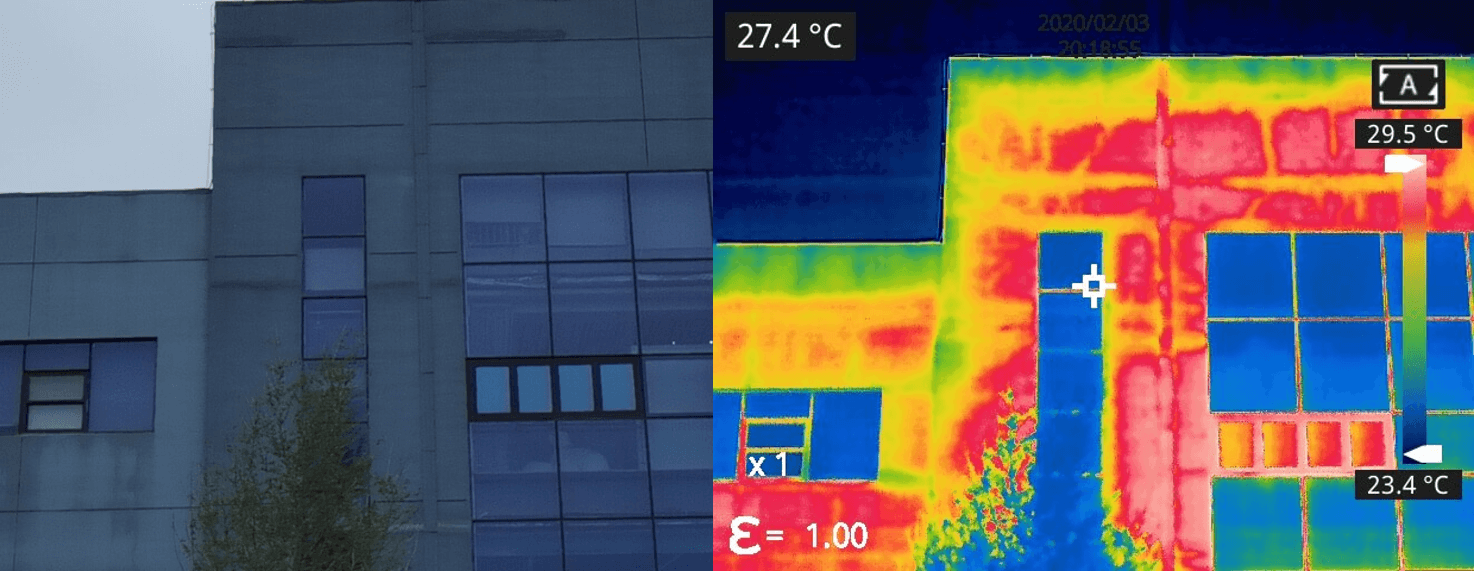

- Assessing Energy Efficiency: One of the most common uses of thermal imaging in buildings is conducting energy audits. By scanning doors, windows, and walls, thermal cameras can detect air leaks, insulation gaps, and heat loss in HVAC systems. This helps identify areas where energy is being wasted, enabling property owners to make necessary improvements and reduce utility costs.

- Detecting Moisture Issues: Moisture problems in buildings can lead to mold growth and structural damage if not addressed early. Thermal imaging cameras are highly effective at identifying moisture sources because wet areas tend to be cooler than dry ones. This makes it easy to spot problem areas in walls, roofs, and foundations before significant damage occurs. Using thermal imaging for moisture detection can prevent costly repairs down the line.

- Roof Inspections: Identifying roof issues without invasive methods can be challenging. Thermal imaging offers a non-intrusive solution by detecting hidden leaks, moisture buildup, and structural weaknesses. This allows inspectors to assess the condition of a roof efficiently and accurately, saving time and reducing the need for physical testing.

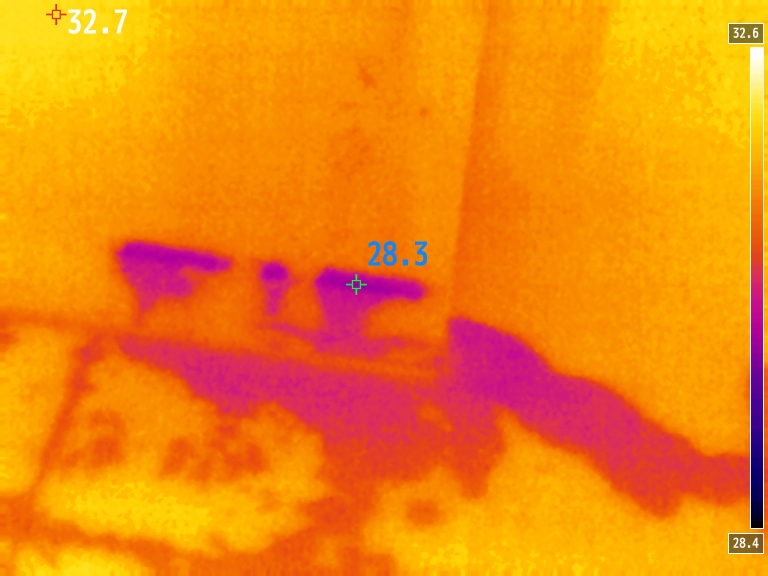

- Electrical System Checks: Many electrical components operate continuously within a building, and overheating can lead to serious hazards like fires. Thermal imaging cameras help identify hot spots that may indicate faulty connections, overloaded circuits, or failing equipment. Early detection of these issues can prevent accidents and save money on emergency repairs.

Benefits of Using Thermal Imaging Cameras in Building Diagnostics

- Fast and Efficient: Thermal imaging cameras allow for quick assessments by scanning large areas in a single view. Unlike traditional temperature measurement tools that require checking each component individually, thermal imaging provides an instant overview of the entire structure.

- Cost-Effective: Regular inspections using thermal imaging can help identify potential problems before they escalate, leading to significant cost savings. Addressing minor issues early can prevent expensive repairs and extend the lifespan of building systems.

- Non-Invasive: Traditional methods of inspecting for leaks or structural issues often involve drilling holes or removing sections of walls. Thermal imaging eliminates the need for such intrusive procedures, preserving the integrity of the building while still providing accurate results.

In conclusion, thermal imaging is a powerful tool for building diagnostics, offering a fast, non-invasive, and reliable method for assessing a building’s condition. From energy efficiency audits to moisture detection and electrical inspections, thermal imaging cameras play a crucial role in maintaining the safety, efficiency, and longevity of buildings. Their ability to reveal hidden issues makes them an essential asset for professionals in construction, facility management, and real estate. Incorporating thermal imaging into routine inspections can lead to better maintenance practices and long-term cost savings.

Tempsens Instruments offers a range of thermal imaging solutions tailored for building diagnostics. Our Thermeye640 model features a high-resolution 640x480 display, making it ideal for detailed inspections. The resolution of the camera is critical when identifying small details, especially in complex structures. If you're looking for a thermal imaging solution that meets your specific needs, contact us today. Our experts will guide you toward the best options for your application.

Read more at : catalog/non-contact-temperature-sensors/thermal-imagers/portable-thermal-imaging-camera.html

PTFE Large Products have the highest melting point and is capable of continued service at -180-260 C. PTFE is a melt processible resin capable of continued service at 204 C. PTFE products are used as gasket and packing materials in chemical processing equipment; as electrical insulation for maximum reliabillity; and in bearings, seals, piston rings and other mechanical applications, especially those require anti-stick characteristics. PTFE has excellent thermal and electrical insulation properties. it has a low coefficient of friction.

PTFE Large Products,Large Teflon Bush,PTFE Spring Seal,Big Size Ptfe Ring

LIAONING HUARI NEW MATERIALS CO., LTD. , https://www.ptfebush.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)