Mining Tools — A Guide to Mining Equipment and Mining Machines

The term "mining tools" refers broadly to all the equipment and machines used in the extraction of minerals from the earth. These tools are essential for mining operations, which supply materials for everything from everyday consumer goods to major energy sources.

Minerals like uranium and coal play a crucial role in global energy production, with coal alone accounting for over 50% of the U.S. energy supply. These resources are obtained through various types of mining techniques, each requiring specific tools and machinery.Before diving into the specific tools used in different mining methods, it's important to understand the overall process and how these tools are applied in real-world scenarios.

This guide will explore the four main types of mining—underground, open-pit, placer, and in-situ—and the corresponding equipment used in each. We’ll also look at the general steps involved in mining, such as extraction, material handling, and processing.

Types of Mining Methods

Mining is categorized into four main types: underground, open surface (or open-pit), placer, and in-situ. Each method has its own set of tools and processes, depending on the type of mineral being extracted and the location of the deposit.

Regardless of the method, most mining operations follow a basic sequence:

- Extraction. This involves digging, drilling, or blasting to access the minerals.

- Material Handling. Once extracted, materials are sorted, and valuable minerals are transported to processing sites while waste is sent elsewhere.

- Material Processing. Minerals are then refined, crushed, or smelted to prepare them for market.

Surface Mining Methods

Surface mining is used when minerals are located near the earth’s surface. Common surface mining techniques include:

- Strip Mining: Removes layers of soil and rock to expose the mineral beneath, often used for coal.

- Open-Pit Mining: Involves creating large pits by drilling and blasting, commonly used for metals like silver.

- Quarrying: Extracts hard stones like granite and marble by cutting blocks from exposed rock faces.

- In-Situ Leaching (ISL): Dissolves minerals in place without removing rock, typically used for uranium.

- Placer Mining: Uses water and pans to extract gold from sand or gravel deposits.

Open-pit mine | Source: Adam Rhodes on Unsplash

Open-pit mine | Source: Adam Rhodes on Unsplash

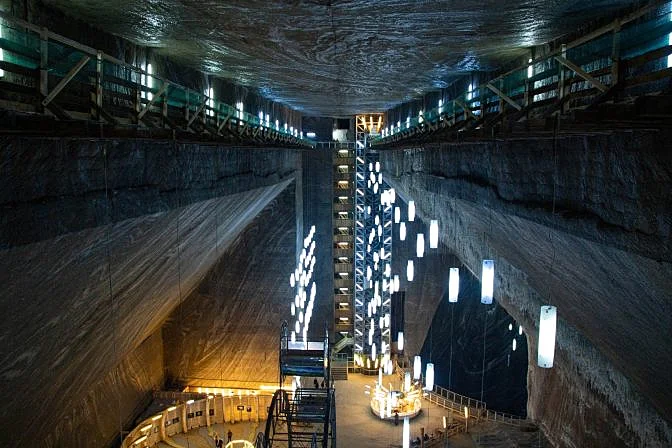

Underground Mining Methods

When minerals are too deep to be accessed through surface methods, underground mining is used. This approach requires specialized equipment and careful planning due to the confined and hazardous nature of the environment.

Common underground mining techniques include:

- Blast Mining: Uses explosives to break up rock and create access tunnels.

- Room and Pillar Mining: Creates pillars to support the mine roof while extracting minerals around them.

- Retreat Mining: Removes pillars to extract remaining minerals, a high-risk process that requires precision.

- Block Caving: Allows rock to collapse naturally after creating a void below it.

- Cut and Fill Mining: Excavates horizontal slices and fills them before moving to the next level.

- Longwall Mining: Used in coal mines, this method uses a long shearer to extract coal continuously.

- Shrinkage Stope Mining: Efficiently extracts steep orebodies by blasting and backfilling in stages.

Salt mine | Source: Szabolcs Molnar from Pixabay

Salt mine | Source: Szabolcs Molnar from Pixabay

Mining Equipment for Soft Rock vs. Hard Rock Mines

Soft rock mining typically does not require explosives, whereas hard rock mining relies heavily on them. Soft rocks like salt and potash can be extracted using mechanical tools, while harder materials like copper and gold need blasting and drilling equipment.

Mining Tools and Equipment

There are numerous types of mining tools, each designed for specific tasks and environments. To help organize this information, we've grouped them by mining method and function.

Here's a general list of categories of mining tools and equipment:

- Miner Tools: Handheld tools like pickaxes, shovels, and chisels.

- Mining PPE: Personal protective equipment such as helmets, respirators, and safety gear.

- Surface Mining Equipment: Heavy machinery used for open-pit and strip mining.

- Underground Mining Equipment: Specialized tools for working in enclosed spaces.

Mining PPE

Personal Protective Equipment (PPE) is vital for miner safety. Typical items include:

- Air respirators

- Cap lights

- Hearing protection

- Miner’s pouches

- Protective communications devices

- Protective eyewear and headgear

- Reflective clothing

- Self-rescuers

Surface Mining Equipment

Surface mining uses a range of heavy machinery, including:

- Blasthole drills

- Bucket-wheel excavators

- Dozers

- Dragline excavators

- Graders

- Highwall miners

- Mining trucks

- Drones

Blasthole drill | Source: Cat Models

Blasthole drill | Source: Cat Models

Underground Mining Equipment

Underground mining relies on compact and durable equipment, such as:

- Crane lifts

- Continuous miners

- Underground drones

- Jumbo drills

- Loaders and haulers

- Longwall mining machines

- Refuge chambers

- Shotcrete machines

- Ventilation systems

Elios 3 drone | Source: Flyability

Elios 3 drone | Source: Flyability

Other Mining Tools

In addition to the above, there are many other tools used in both surface and underground mining, such as hoppers, conveyors, crushers, and screens. These tools help transport and process extracted materials efficiently.

As technology advances, new tools like LiDAR-equipped drones are becoming more common, especially in underground mining. These tools enhance safety, accuracy, and efficiency in surveying and inspecting mines.

The mining industry, though traditional, is slowly embracing modern solutions to improve productivity and worker safety. With ongoing innovation, the future of mining looks increasingly automated and data-driven.

Shandong Jianlong Special Steel Co., Ltd. , https://www.jianlongsteelpipe.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)