Mining Tools — A Guide to Mining Equipment and Mining Machines

The term "mining tools" refers broadly to all the equipment and machines used in the extraction of minerals from the earth. These tools are essential for accessing and processing a wide range of resources, from precious metals to energy sources like coal and uranium.

Minerals are embedded in almost every product we use daily—from the electronics in our phones to the materials in our cars and even the jewelry we wear. For instance, uranium and coal contribute significantly to the U.S. energy supply, accounting for nearly half of the country's power generation.These valuable resources are obtained through various mining techniques and specialized equipment. Understanding the different methods of mining is key to appreciating the tools used in each process.

This guide will explore the different types of mining methods, followed by an in-depth look at the specific tools and machines used in each category. Whether you're a professional in the industry or simply curious about how mining works, this article aims to provide a clear and comprehensive overview.

Types of Mining Methods

Mining can be categorized into four main types: underground, open-pit (surface), placer, and in-situ mining. Each method has its own set of tools and equipment tailored to the specific conditions and materials being extracted.

Regardless of the method, most mining operations follow a basic sequence of steps: extraction, material handling, and material processing. Let’s break these down:

- Extraction. This involves digging, drilling, or blasting to access the minerals beneath the surface.

- Material Handling. Once extracted, the materials are sorted, with target minerals sent to processing sites and waste materials moved to designated areas.

- Material Processing. The final stage where minerals are refined, crushed, or smelted to prepare them for market.

Surface Mining Methods

Surface mining is used when minerals are located close to the Earth’s surface. Common techniques include:

- Strip Mining: Removes layers of overburden to reach mineral deposits, often used for coal.

- Open-Pit Mining: Involves creating large pits to extract minerals like silver and copper.

- Quarrying: Used for extracting hard stones such as granite and marble.

- In-Situ Leaching (ISL): Dissolves minerals in place without removing rock, commonly used for uranium.

- Placer Mining: Extracts gold from sand or gravel using pans and water.

Open-pit mine | Source: Adam Rhodes on Unsplash

Open-pit mine | Source: Adam Rhodes on Unsplash

Underground Mining Methods

Some minerals are too deep to be accessed through surface mining, so underground methods are employed. These include:

- Blast Mining: Uses explosives to break up rock and create access points.

- Room and Pillar Mining: Creates pillars to support the mine roof while extracting minerals around them.

- Retreat Mining: Removes pillars after initial extraction, requiring careful planning to avoid collapse.

- Block Caving: A large-scale method that allows rock to collapse naturally after initial blasting.

- Longwall Mining: Commonly used in coal mines, this method uses a shearer to cut coal from the face.

- Shrinkage Stope Mining: Used for steep ore bodies, this method ensures efficient extraction and backfilling.

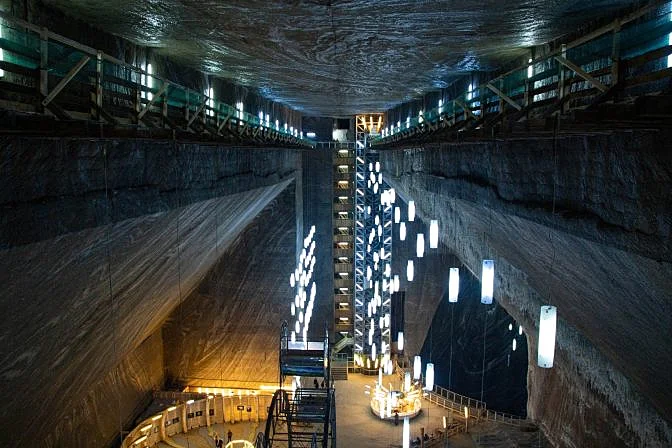

Salt mine | Source: Szabolcs Molnar from Pixabay

Salt mine | Source: Szabolcs Molnar from Pixabay

Mining Equipment for Soft Rock vs. Hard Rock Mines

Soft rock mining typically doesn’t require explosives, while hard rock mining does. Examples of soft rocks include salt, coal, and bauxite, whereas hard rocks like copper, gold, and uranium require more powerful tools.

Hard rock mining relies heavily on hydraulic drills and explosives, while soft rock mining uses specialized machinery that avoids the need for detonation.

Mining Tools and Equipment

There are numerous types of mining tools, each designed for specific tasks. Instead of listing them all at once, we’ve organized them by mining method to provide a clearer understanding.

Here’s a general list of mining tools and equipment categories:

- Miner Tools: Basic hand tools like pickaxes and shovels.

- Mining PPE: Personal protective equipment such as helmets, respirators, and reflective clothing.

- Surface Mining Equipment: Heavy machinery used above ground, including excavators and trucks.

- Underground Mining Equipment: Specialized tools designed for confined spaces, like loaders and ventilation systems.

Now that we’ve covered the basics, let’s dive deeper into each category.

Mining PPE

Miners rely on personal protective equipment (PPE) to stay safe in hazardous environments. Key items include:

- Air respirator systems

- Cap lights

- Hearing protection

- Miner’s pouches

- Protective communications devices

- Protective eyewear and headgear

- Reflective clothing

- Self-rescuers

Surface Mining Equipment

Surface mining requires heavy machinery, including:

- Blasthole drills

- Bucket-wheel excavators

- Dozers

- Dragline excavators

- Graders

- Highwall miners

- Mining trucks

- Drones for surveying and inspection

Blasthole drill | Source: Cat Models

Blasthole drill | Source: Cat Models

Underground Mining Equipment

Underground mining tools include:

- Crane lifts

- Continuous miners

- Underground drones

- Jumbo drills

- Loaders and haulers

- Longwall mining machines

- Refuge chambers

- Rock dusters

- Roof bolters

- Shotcrete machines

- Ventilation systems

It's important to note that many underground machines are designed to operate without emissions, ensuring safety in enclosed spaces.

Elios 3 drone | Source: Flyability

Elios 3 drone | Source: Flyability

Other Mining Tools

Additional tools used in both surface and underground mining include hoppers, chutes, conveyor belts, crushers, and screens. These tools help in transporting and processing mined materials efficiently.

As the mining industry evolves, technology like LiDAR and drones is becoming increasingly vital. Drones such as the Elios 3 are now used to inspect tunnels and collect data safely, making the process faster and more efficient.

While mining is an ancient practice, it continues to adapt to modern needs. With new technologies emerging, the future of mining looks more efficient, safer, and sustainable than ever before.

Wear Resistant Steel Plate,Wear Resistant Stainless Steel Plate,Wear Abrasion Resistant Steel Plate,Wear Steel Plate

Shandong Jianlong Special Steel Co., Ltd. , https://www.jianlongsteelpipe.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)