Learn about Custom Sheet Metal Boxes

- Significance of custom sheet metal boxes in various industries.

- Benefits, design process, material selection, fabrication techniques, and customization options for custom sheet metal boxes.

- How to choose the right fabrication partner and maintain sheet metal boxes for longevity.

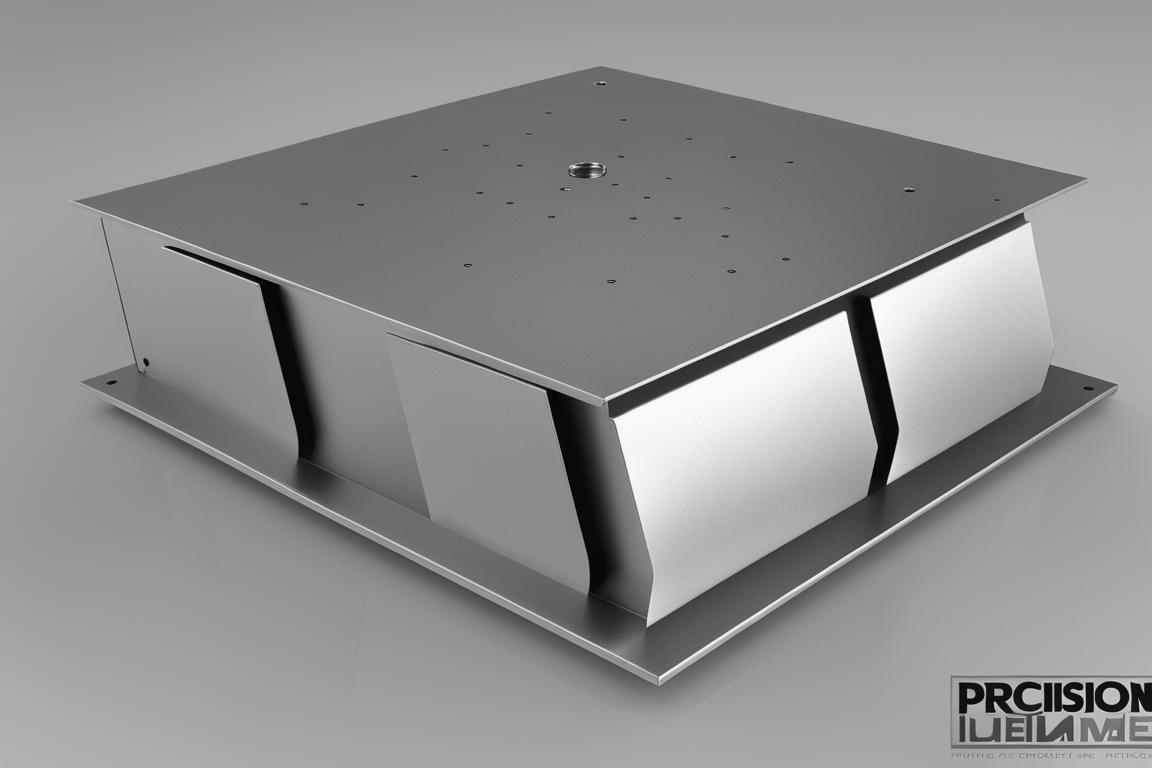

Are you curious about how custom sheet metal boxes can transform your storage or transport needs? These specialized enclosures are increasingly popular across multiple industries due to their adaptability and precision. Unlike standard products, custom sheet metal boxes are made to fit specific requirements, offering a tailored solution for everything from housing delicate electronics to protecting industrial components. Their flexibility makes them essential in sectors like aerospace, automotive, and medical equipment manufacturing.

Benefits of Custom Sheet Metal Boxes

Custom sheet metal boxes come with a range of advantages that make them superior to generic alternatives. One of the biggest benefits is precision. By designing the box exactly to your specifications, you ensure it fits perfectly into your space or application. The durability of sheet metal also ensures long-lasting performance, making these boxes ideal for heavy-duty use. Plus, they offer custom aesthetics, allowing you to choose colors, finishes, and even logos to match your brand or project needs.

Design and Engineering Process

The journey from concept to finished product involves careful planning and engineering. It starts with CAD (Computer-Aided Design), where engineers create detailed 3D models to visualize the final product. This stage helps identify potential issues before production begins. Then comes prototyping, where a sample is built and tested. This iterative process ensures the design meets all functional and aesthetic expectations before mass production.

CAD Design in Custom Sheet Metal Boxes

CAD software plays a key role in ensuring accuracy throughout the design phase. It allows designers to simulate real-world conditions and test different configurations. This not only improves the final outcome but also reduces errors and costs during the actual manufacturing process.

Material Selection for Custom Sheet Metal Boxes

Choosing the right material is crucial for the performance of your custom sheet metal box. Common options include aluminum, which is lightweight and corrosion-resistant; stainless steel, known for its strength and sleek appearance; and carbon steel, which offers high durability at an affordable price. Each material has unique properties that make it suitable for different environments and applications.

| Fabrication Technique | Description |

|---|---|

| Cutting | Shaping metal sheets according to design specifications using laser cutting or shearing methods |

| Bending | Forming the structural components of the box through bending techniques |

| Welding | Joining individual components together to create a sturdy structure using TIG or MIG welding |

| Finishing | Enhancing the appearance and durability of the box through treatments like powder coating or anodizing |

Fabrication Techniques for Custom Sheet Metal Boxes

Creating custom sheet metal boxes requires a combination of precise techniques. Cutting uses tools like lasers or shears to shape the metal. Bending forms the sides and corners, while welding joins the pieces together for a strong structure. Finally, finishing processes such as painting or anodizing improve both looks and protection against wear and tear.

Welding in Custom Sheet Metal Boxes

Welding is a critical step in assembling the box. Techniques like TIG and MIG provide strong, clean welds that enhance the box’s durability and appearance. Proper welding ensures the box remains intact under stress and maintains its structural integrity over time.

Precision and Quality Control Measures

Maintaining precision and quality control is vital for producing reliable custom sheet metal boxes. Every stage of the process—from design to finishing—is checked to ensure it meets exact specifications. This attention to detail guarantees that each box performs as intended and lasts for years.

Customization Options for Sheet Metal Boxes

Custom sheet metal boxes offer endless possibilities for personalization. You can choose the size, shape, color, and even add your company logo. This level of customization allows you to create a box that not only serves its purpose but also reflects your brand identity. Whether you need a simple storage unit or a high-end enclosure, the options are nearly limitless.

Case Studies of Custom Sheet Metal Box Projects

Here are a few examples of how custom sheet metal boxes are used in real-world applications:

- Electronics Industry: Custom enclosures protect sensitive components and help organize internal wiring.

- Medical Equipment: Boxes designed for medical devices must meet strict hygiene and safety standards.

- Automotive Sector: Custom boxes optimize storage and transport for parts, improving efficiency in manufacturing and logistics.

Current Industry Trends in Custom Sheet Metal Box Fabrication

The industry is evolving rapidly with new technologies and sustainable practices. Digital design tools have improved accuracy and speed, while eco-friendly materials and recycling programs are becoming more common. Automation is also playing a bigger role, increasing efficiency and reducing waste in the production process.

Choosing the Right Fabrication Partner

Selecting the right manufacturer is crucial for success. Look for partners with experience in custom projects, advanced technology, and a proven track record. A good fabrication company will work closely with you to understand your needs and deliver high-quality results on time and within budget.

Maintenance and Care Guidelines for Sheet Metal Boxes

To keep your custom sheet metal boxes in top condition, regular maintenance is essential. Clean them periodically to prevent rust and damage. Avoid exposing them to harsh chemicals or extreme temperatures. Lubricate moving parts like hinges and latches to ensure smooth operation. With proper care, your custom sheet metal boxes can last for many years.

Future Prospects in Custom Sheet Metal Box Fabrication

The future of custom sheet metal box manufacturing looks bright. Innovations like 3D printing and smart integration are opening up new possibilities. As sustainability becomes more important, we’ll likely see more eco-friendly materials and energy-efficient processes. These trends will continue to shape the industry and improve the value of custom sheet metal solutions.

FAQs

Who can benefit from custom sheet metal boxes?

Businesses in need of precise and durable storage solutions.

What makes custom sheet metal boxes unique?

They are tailored to specific dimensions and designs.

How are custom sheet metal boxes fabricated?

They are crafted using precision sheet metal fabrication techniques.

Who can I contact for custom sheet metal box orders?

You can reach out to experienced sheet metal fabrication companies.

What if I need a custom sheet metal box quickly?

Some fabrication companies offer expedited services for urgent orders.

How durable are custom sheet metal boxes?

Custom sheet metal boxes are incredibly sturdy and long-lasting.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who can benefit from custom sheet metal boxes?", "acceptedAnswer": {"@type": "Answer", "text": "Businesses in need of precise and durable storage solutions."}}, {"@type": "Question", "name": "What makes custom sheet metal boxes unique?", "acceptedAnswer": {"@type": "Answer", "text": "They are tailored to specific dimensions and designs."}}, {"@type": "Question", "name": "How are custom sheet metal boxes fabricated?", "acceptedAnswer": {"@type": "Answer", "text": "They are crafted using precision sheet metal fabrication techniques."}}, {"@type": "Question", "name": "Who can I contact for custom sheet metal box orders?", "acceptedAnswer": {"@type": "Answer", "text": "You can reach out to experienced sheet metal fabrication companies."}}, {"@type": "Question", "name": "What if I need a custom sheet metal box quickly?", "acceptedAnswer": {"@type": "Answer", "text": "Some fabrication companies offer expedited services for urgent orders."}}, {"@type": "Question", "name": "How durable are custom sheet metal boxes?", "acceptedAnswer": {"@type": "Answer", "text": "Custom sheet metal boxes are incredibly sturdy and long-lasting."}}]}Lincoln Car Brake Pads,Truck Rear Brake Pads,Auto Brake System Brake Pads

DONGYING BORUI BRAKE SYSTEM CO.,LTD. , https://www.boruiauto.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)