Learn About Custom Sheet Metal Boxes

- Why custom sheet metal boxes are essential in different industries.

- The advantages, design process, material choices, manufacturing methods, and customization options available for custom sheet metal boxes.

- How to select the right manufacturer and maintain your sheet metal boxes for long-term use.

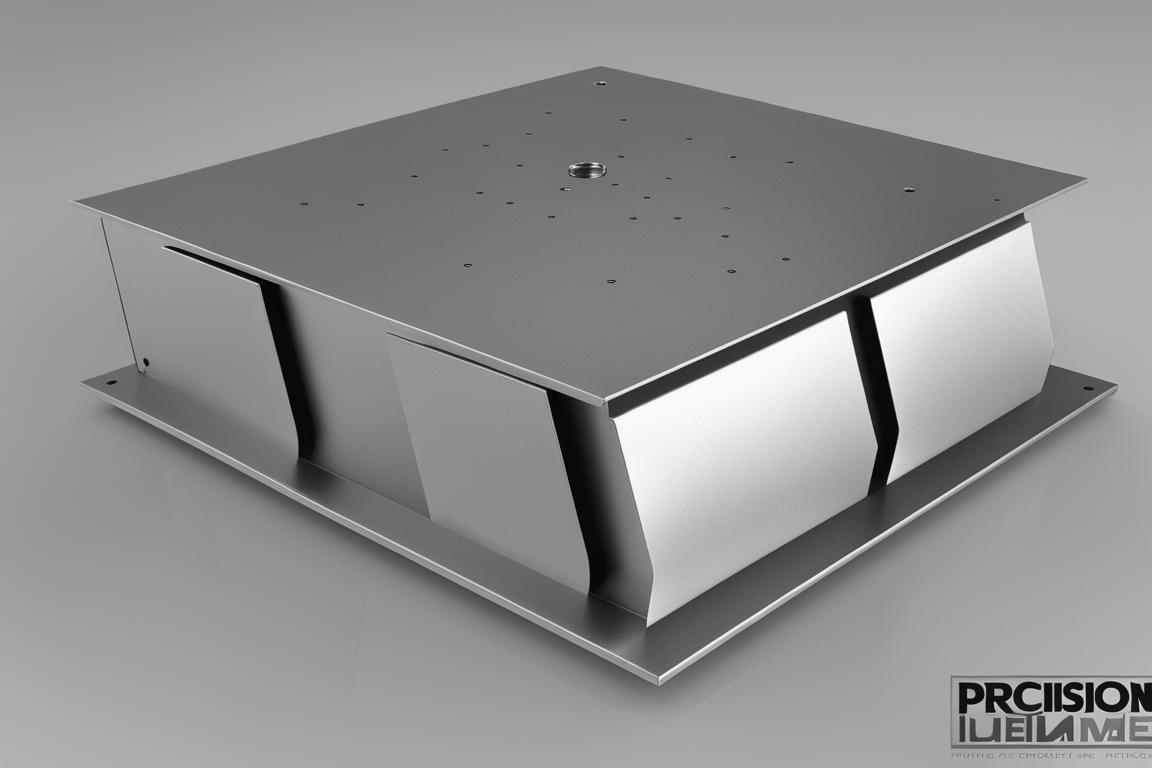

Are you curious about how custom sheet metal boxes can be a game-changer for your business? In today’s fast-paced industrial environment, the demand for custom sheet metal boxes has been steadily increasing. These boxes are not just generic storage solutions—they’re tailored to fit specific needs with precision and efficiency. Whether it's for protecting sensitive electronics, housing critical components, or ensuring safe transportation of goods, custom sheet metal boxes offer a level of flexibility and durability that off-the-shelf products simply can’t match.

The Benefits of Custom Sheet Metal Boxes

Custom sheet metal boxes come with a range of benefits that make them a top choice across various sectors. One of the most significant advantages is precision. Unlike standard boxes, these are designed to fit exactly what you need—whether it's a unique size, shape, or internal layout. This ensures maximum space utilization and optimal functionality. Additionally, durability is a key feature, as sheet metal is known for its strength and resistance to wear and tear. Lastly, customization allows for a polished look through coatings, finishes, and branding elements, making the box both functional and visually appealing.

Design and Engineering Process

Creating a custom sheet metal box involves a detailed design and engineering process to ensure it meets all specifications. It starts with CAD (Computer-Aided Design), where engineers develop 3D models that guide the entire fabrication process. Prototyping follows to test the design before mass production, allowing for adjustments and improvements. This careful planning ensures that the final product is not only accurate but also efficient and cost-effective.

CAD Design in Custom Sheet Metal Boxes

CAD software plays a vital role in the design phase by enabling precise measurements and visualizations. Engineers can simulate real-world conditions and identify potential issues early on, saving time and resources during the manufacturing stage.

Material Selection for Custom Sheet Metal Boxes

The choice of material significantly impacts the performance and lifespan of a custom sheet metal box. Common materials include aluminum, stainless steel, and carbon steel, each offering unique properties. For example, aluminum is lightweight and corrosion-resistant, making it ideal for applications where weight is a concern. Stainless steel provides superior strength and a sleek appearance, often used in high-end or medical environments. Carbon steel is more economical and durable, suitable for heavy-duty uses.

| Fabrication Technique | Description |

|---|---|

| Cutting | Shaping metal sheets according to design specifications using laser cutting or shearing methods |

| Bending | Forming the structural components of the box through bending techniques |

| Welding | Joining individual components together to create a sturdy structure using TIG or MIG welding |

| Finishing | Enhancing the appearance and durability of the box through treatments like powder coating or anodizing |

Fabrication Techniques for Custom Sheet Metal Boxes

Custom sheet metal boxes are made using a combination of advanced fabrication techniques. The process begins with cutting, where metal sheets are shaped precisely using tools like lasers or shears. Next, bending forms the structural parts of the box. Then, welding joins these parts into a strong, cohesive unit. Finally, finishing processes such as painting or anodizing enhance both the look and longevity of the box.

Welding in Custom Sheet Metal Boxes

Welding is a crucial step in ensuring the box’s structural integrity. Techniques like TIG and MIG welding are commonly used to produce clean, strong joints that hold up under stress and environmental exposure.

Precision and Quality Control Measures

Maintaining precision and quality control throughout the production process is essential. Each step is carefully monitored to ensure that the final product meets exact specifications. This attention to detail guarantees that every custom sheet metal box is built to last and perform reliably in its intended application.

Customization Options for Sheet Metal Boxes

One of the biggest advantages of custom sheet metal boxes is the ability to tailor them to your exact needs. From choosing the size, shape, and color to adding logos, labels, or even special features like hinges or latches, the possibilities are endless. This level of personalization makes the boxes not only functional but also aligned with your brand identity and operational requirements.

Real-World Applications of Custom Sheet Metal Boxes

Custom sheet metal boxes are used across multiple industries, including:

- Electronics: Protecting delicate components from damage and static.

- Medical Equipment: Ensuring safe transport and storage of critical devices.

- Automotive: Storing and organizing parts efficiently in manufacturing facilities.

Industry Trends in Custom Sheet Metal Box Fabrication

The industry is continuously evolving with new technologies and trends. Digital design tools have improved accuracy and speed, while sustainable practices are becoming more common. Automation is also playing a bigger role, reducing errors and improving productivity. These advancements are helping manufacturers deliver better quality products faster and more efficiently.

Choosing the Right Fabrication Partner

Selecting the right manufacturer is key to getting the best results. Look for partners with experience, good reviews, and the capability to handle complex designs. A reliable fabrication company will ensure your project is completed on time, within budget, and to your satisfaction.

Maintenance Tips for Sheet Metal Boxes

To keep your custom sheet metal boxes in top condition, regular maintenance is important. Clean them regularly to prevent rust or dirt buildup. Avoid exposing them to harsh chemicals or extreme temperatures. If they have moving parts, lubricate them periodically to ensure smooth operation. Following these tips can extend their lifespan and maintain their performance.

The Future of Custom Sheet Metal Box Fabrication

Looking ahead, the future of custom sheet metal box fabrication is bright. Innovations like 3D printing and smart integration are opening new possibilities. Sustainability is also gaining traction, with more eco-friendly materials and energy-efficient processes being adopted. As technology advances, we can expect even more personalized, efficient, and environmentally responsible solutions in the years to come.

FAQs

Who can benefit from custom sheet metal boxes?

Businesses that require precise and durable storage or transport solutions.

What makes custom sheet metal boxes unique?

They are designed to meet specific dimensions, shapes, and functions, offering a tailored solution.

How are custom sheet metal boxes fabricated?

They are created using advanced sheet metal fabrication techniques like cutting, bending, welding, and finishing.

Who should I contact for custom sheet metal box orders?

You can reach out to experienced sheet metal fabrication companies.

What if I need a custom sheet metal box quickly?

Many manufacturers offer expedited services for urgent orders.

How durable are custom sheet metal boxes?

Custom sheet metal boxes are highly durable and built to last.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who can benefit from custom sheet metal boxes?", "acceptedAnswer": {"@type": "Answer", "text": "Businesses that require precise and durable storage or transport solutions."}}, {"@type": "Question", "name": "What makes custom sheet metal boxes unique?", "acceptedAnswer": {"@type": "Answer", "text": "They are designed to meet specific dimensions, shapes, and functions, offering a tailored solution."}}, {"@type": "Question", "name": "How are custom sheet metal boxes fabricated?", "acceptedAnswer": {"@type": "Answer", "text": "They are created using advanced sheet metal fabrication techniques like cutting, bending, welding, and finishing."}}, {"@type": "Question", "name": "Who should I contact for custom sheet metal box orders?", "acceptedAnswer": {"@type": "Answer", "text": "You can reach out to experienced sheet metal fabrication companies."}}, {"@type": "Question", "name": "What if I need a custom sheet metal box quickly?", "acceptedAnswer": {"@type": "Answer", "text": "Many manufacturers offer expedited services for urgent orders."}}, {"@type": "Question", "name": "How durable are custom sheet metal boxes?", "acceptedAnswer": {"@type": "Answer", "text": "Custom sheet metal boxes are highly durable and built to last."}}]}Korean Car Brake Pads,Wva 24503 Car Brake Pads,Car Brake Accessories Brake Pads,Wva24317 Car Brake Accessories Brake Pads

DONGYING BORUI BRAKE SYSTEM CO.,LTD. , https://www.boruiauto.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)