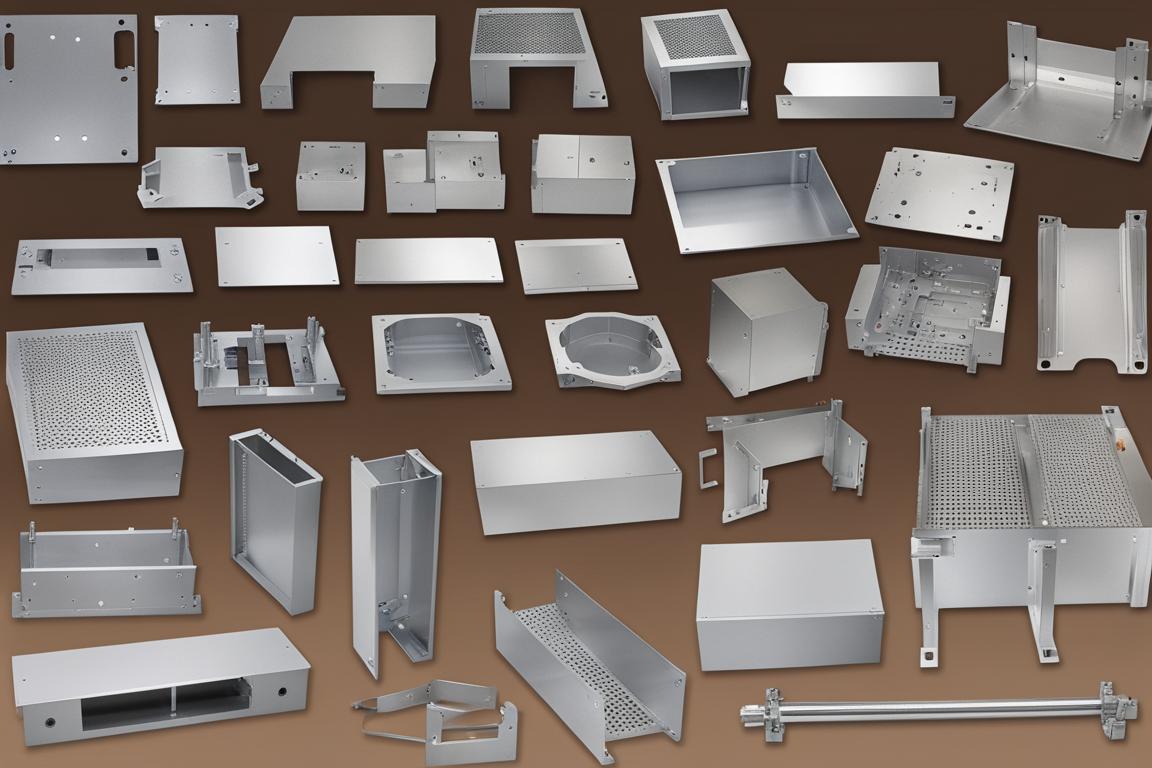

In the world of electronics, ensuring both protection and performance is essential. Electronic enclosures serve as a critical component in safeguarding sensitive internal parts from external threats like dust, moisture, and physical damage. These enclosures not only provide a protective barrier but also offer structural support, aid in heat management, and contribute to the overall efficiency and reliability of electronic devices.

Discover What Makes Precision Sheet Metal Enclosure Manufacturers Stand Out

- Understand the key role of electronic enclosures in device protection and functionality.

- Explore how precision sheet metal fabrication ensures high-quality, durable enclosures.

- Learn about the different types of enclosures, materials used, and design considerations for optimal performance.

What Are Electronic Enclosures and Why Do They Matter?

Electronic enclosures, often referred to as casings or chassis, are designed to house and protect internal components. These structures come in various forms—ranging from compact units for small devices to large-scale systems for industrial use. Made from materials such as steel, aluminum, or composites, they are engineered to withstand harsh conditions while maintaining the integrity of the electronics inside.

Why Electronic Enclosures Are Essential for Device Protection

The main purpose of an electronic enclosure is to shield delicate circuitry from environmental factors that could cause failure or damage. Whether it's moisture, temperature fluctuations, or mechanical stress, these enclosures ensure that devices remain functional under a wide range of conditions. Additionally, they help manage electromagnetic interference (EMI) and radio frequency interference (RFI), which can disrupt signal quality and lead to malfunctions.

The Role of Precision Sheet Metal Fabrication in Enclosure Manufacturing

Precision sheet metal fabrication is a key process in creating reliable and high-performance electronic enclosures. This method allows for exact measurements and consistent quality, ensuring that each unit meets strict industry standards. The attention to detail involved in this process not only enhances the appearance of the enclosure but also improves its strength and durability.

How Precision Affects Quality and Customization

When enclosures are manufactured with precision, they fit perfectly around the components they house, reducing the risk of misalignment or damage. This level of accuracy also allows for complex designs and custom features that cater to specific application needs. Whether it's a simple housing unit or a highly specialized system, precision fabrication ensures the final product is both functional and efficient.

Durability, Performance, and Longevity

The quality of sheet metal fabrication has a direct impact on the longevity and performance of enclosures. Well-made enclosures resist corrosion, deformation, and wear, making them ideal for long-term use. Moreover, precise manufacturing techniques enhance thermal management, allowing heat to dissipate efficiently and preventing overheating—a crucial factor in maintaining device performance, especially in demanding environments.

Common Types of Enclosures in Precision Sheet Metal Fabrication

There are many types of enclosures used in electronic systems, each designed for specific applications. Some common varieties include rack-mount enclosures for servers and networking equipment, junction boxes for electrical connections, handheld enclosures for portable devices, and wall-mount enclosures for space-saving installations.

Key Features of Common Enclosures

| Advantages | Description |

|---|---|

| Customization | Enclosures can be tailored to meet unique design and functional requirements. |

| High-Quality Finish | Smooth and professional finishes improve aesthetics and reduce wear over time. |

| Enhanced Protection | Provides superior defense against environmental and mechanical hazards. |

| Structural Strength | Strong construction ensures long-lasting performance and stability. |

| Efficient Heat Dissipation | Helps maintain safe operating temperatures for enclosed electronics. |

| Enclosure Type | Purpose |

|---|---|

| Rack-Mount Enclosures | Used in data centers to house servers and network gear. |

| Junction Boxes | Protect wiring and electrical connections in industrial settings. |

| Handheld Enclosures | Designed for portable tools, scanners, and remote controls. |

| Wall-Mount Enclosures | Save space and are ideal for control panels and security systems. |

To further strengthen the credibility of this article for enclosure manufacturers, including real-world case studies or examples of successful projects would add value. Additionally, providing information about the experience of the writers or experts involved, along with references to trusted sources, can significantly increase the article’s authority and trustworthiness.

Frequently Asked Questions

Who are the top enclosure manufacturers in precision sheet metal fabrication?

Some leading names in this field include ABC Enclosures and XYZ Fabrication, known for their high-quality and customized solutions.

What services do precision sheet metal fabrication companies offer?

These manufacturers typically provide custom design, laser cutting, bending, welding, and finishing services tailored to client needs.

How can I request a quote from a precision sheet metal manufacturer?

You can contact them through their official website or reach out directly via phone or email to get a detailed quote.

What makes precision sheet metal enclosure manufacturers stand out?

They focus on delivering accurate, durable, and customized products that meet specific industry and application requirements.

How long does it take to complete an enclosure project?

Project timelines vary depending on complexity, but most projects take between a few weeks to a couple of months.

Are precision sheet metal enclosures expensive?

While costs depend on the scope of work, many manufacturers offer competitive pricing for their specialized services.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who are the top enclosure manufacturers in precision sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Some leading names in this field include ABC Enclosures and XYZ Fabrication, known for their high-quality and customized solutions."}}, {"@type": "Question", "name": "What services do precision sheet metal fabrication companies offer?", "acceptedAnswer": {"@type": "Answer", "text": "These manufacturers typically provide custom design, laser cutting, bending, welding, and finishing services tailored to client needs."}}, {"@type": "Question", "name": "How can I request a quote from a precision sheet metal manufacturer?", "acceptedAnswer": {"@type": "Answer", "text": "You can contact them through their official website or reach out directly via phone or email to get a detailed quote."}}, {"@type": "Question", "name": "What makes precision sheet metal enclosure manufacturers stand out?", "acceptedAnswer": {"@type": "Answer", "text": "They focus on delivering accurate, durable, and customized products that meet specific industry and application requirements."}}, {"@type": "Question", "name": "How long does it take to complete an enclosure project?", "acceptedAnswer": {"@type": "Answer", "text": "Project timelines vary depending on complexity, but most projects take between a few weeks to a couple of months."}}, {"@type": "Question", "name": "Are precision sheet metal enclosures expensive?", "acceptedAnswer": {"@type": "Answer", "text": "While costs depend on the scope of work, many manufacturers offer competitive pricing for their specialized services."}}]}Gasification board or gasification groove is an auxiliary part of intermediate bunker, ash bucket, flat-based warehouse and cone-based warehouse. It is usually installed at the bottom of material storage warehouse or one side of ash bucket. By connecting preheated air during unloading, this equipment can fluidize powdery material which enhances fluidity of material. This will smoothen the unloading process and avoid particles arching or bridging.

Gasification Equipment, Gasification Generate Electricity Equipment, Biomass Gasification Power Plant Equipment

Rongxin Environmental Protection Equipment Co., Ltd. , https://www.jsrxceramics.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)